After limescale problems from people that don't use surgical steel with hard water and don't have an auto flush that flushes twice with cold water (older generators only flush once), is the 2nd biggest problem that causes leaks and nearly every customer complaint is not having a quality water pressure reducer. Not having one of these attached to your steam generator can cause many problems and expenses down the road.

Make sure the one you get is a quality one or it can rust and corrode also. Depending on your water, you might get by with a cheap one or have to buy a more expensive one.

Contact me so you know all the things that can preserve your generator so you don't have to spend lots of time maintaining your steam generator.

If getting a water pressure reducer make sure you get the type that does not have a cartridge and does not have plastic internals.

All brass and all internals are separate instead of being in a cartridge. The best go down to 10psi without plastic mounts and cartridges. Most plumbers don't do a flush during the first installation that can ruin the pressure reducer from day one.

Steam room maintenance complaints:

The biggest problem is when you have to replace the heaters every few years because they burn out or don’t heat up like they were when they were new due to limescale.

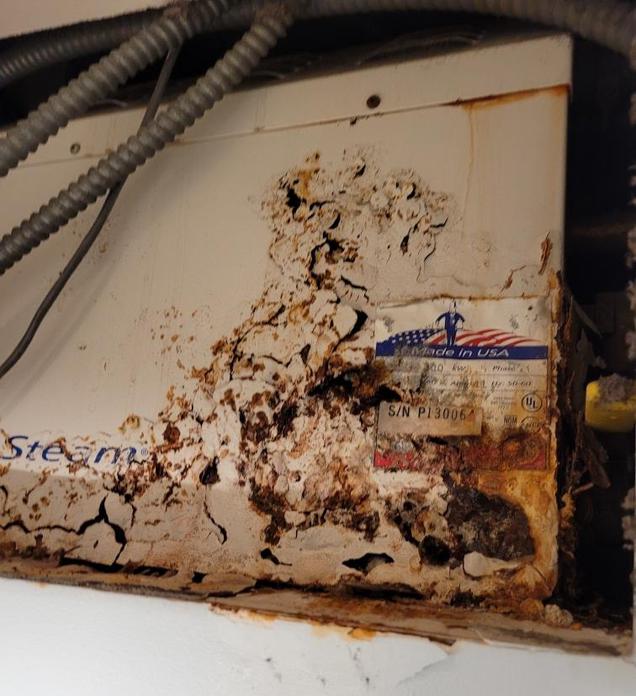

Poor quality heaters may need to be replaced every 2 to 3 years if using the steam room every day. Steam tanks also will need to be replaced if the cleaning system is not as good or its made of cast iron. Even stainless steel heating elements and tanks will corrode away over time. I recommend steam generators with surgical steel tanks and even the heating elements made of surgical steel.

This is way more expensive than the steam generators that have all galvanized steel. This thin coating of zinc will eventually come. This is the cheapest way that I do not promote. Galvanized heating elements corrode quicker because the mineral buildup destroys the heater. I believe it’s a way for the manufacturer to keep making money on someone every few years and done on purpose. For those that don’t want to replace the heaters 5 or 6 times during the lifetime of the heater, please look for non galvanized steel. Stainless steel is 2nd best. 304 grade surgical steel is the best. A good home steam generator should only need one replacement in a 30 year period

Limescale and corrosion is a big problem with steam generators. I urge everyone to invest in surgical steel heating elements if they can afford them.

If the steam generator is taking in hard water, unfiltered water, if not surgical steel heating elements or the tank is galvanized or cast iron there can be high maintenance costs and replacements during the lifetime of the steam generator.

Corrosion of tanks is the 2nd biggest problem after heater element corrosion. 304 grade surgical steel tanks should be used if the water is not filtered and is not soft and you don't want to have to add a chemical solution to the tank every 60 steam sessions.

Maintenance Problems with brands that you need to be aware of before you buy:

I get calls all the time asking if we clean steam generators. I would say about 20% of the people who buy a generator do not know how to run it. They never bought a pressure reducer and if they did, it was probably a plastic one that stopped working and they wonder why their water inlet valves are broken and why its leaking water.

Many people have to send in their generator after the first year and pay about 350 plus shipping both ways to get their generator cleaned or fixed, usually cleaned. This is for residential people that don't buy steam generator that are surgical steel (usually the import ones people buy aren't even stainless steel). Some of these companies use plastic valves and I believe this is just setting people up for failure to send in their generator so the company can make money on them in the future. I have seen generators with cracked and rotted plastic.

Another problem is some companies have their customers add a decalcifying solution to clean their own tanks since the cleaning systems probably are not that good and don't do around a 10 minute double flush and flush all the sediment out. None of the companies I work with would ever tell customers to do this. Those companies tell people to add this chemical to their tank every 30 operational hours. This always leaves a chemical smell and it hard to go away until several sessions later. It's just another inconvenience where if it had surgical steel heating elements, a surgical steel tank and a quality self cleaner this would not be needed under normal use.

This is a picture of a rusted pipe.

DRIP PAN NOTICE:

Most steam generators come with a drip pan or make it option. It is recommended to get a drip pan with certain brands but not if on the basement level. Some steam generators that people don't add a pressure reducers to are more prone to leaking. Also, if it was done with poor soldering this can make it leak. Many people prefer the brands where it is not necessary to get a drip pan. A drip pan should only be used in cases of emergency and should never have to be used. That is when you have a good steam generator and it was properly installed. There are cheap pressure reducers and good ones. Beware of the 50 dollar ones that some people get.

People continue to take steam baths with limescaled heating elements and don't even wonder why their steam room has a mineral smell and doesn't get as hot as when the steam generator was new. Steel heating elements in non pressurized generators should never look like these or the high psi models with auto flushes.

Know before buying a steam generator

Know before buying a steam generator

Know before buying a steam generator

DiscountSteamGenerators.com

We're open now

1-800-336-9285

Ask for Sharon

We're open now

1-800-336-9285

Ask for Alex

DiscountSteamGenerators.com

We're open now

1-800-336-9285

Ask for Sharon

We're open now

1-800-336-9285

Ask for Alex

3 years later....,.

Usually about 3 years later many steam generator heating elements start to build up enough limescale that the 110 to 114 temperature sweet spot range now is at 92 to 110. People complain all the time that their steam generator is not getting hot enough. Those who used to have 20 to 30 minute sessions now take 30 to 45 minutes to heat up their core since the elements are so limescaled that they need to be replaced. The highest psi pressure cooker types give off the driest steam (least condensate) but thee higher the psi, the shorter the elements last. For those who can afford the most expensive generators, please research atmospheric steam generators. These are in a class by themselves.

CUSTOMERS WITH HARD WATER

IF YOU HAVE HARD WATER, THERE ARE SOME GENERATORS THAT YOU WILL NEED TO CHANGE OUT HEATING ELEMENTS EVERY 6 MONTHS EVEN IF YOU HAVE AN AUTOFLUSH.

MAKE SURE YOU DON'T GET THE BRANDS THAT DON'T WORK WELL WITH HARD WATER.

The best steam generators are hand made (TIG Weld) and toxin-free. Tig welded steel joints are the hardest steel elements you can get. Made with no solvents, just pure surgical steel in a weld shop, not machine punched out thin gauge steel imported from China. TIG welding is the slowest method and is hard to master it to get it perfect. Tig welded steam generators have the strongest and highest quality welds and should never rust or leak. The companies that tig weld their steam generators usually take about 2 to 3 weeks to build and are built to order. All TIG welded steam generators are made in North America, never imported from China.

Objective for choosing a steam generator: 1. Stay in the 110 -114 degree zone without too much fluctuation. 2. Stay at 100% humidity with the least condensate. 3. Stay in whole body vasodilation and avoid half body steam therapy. Please take our Steam Generator Quiz. It helps!